chemica@paran.com

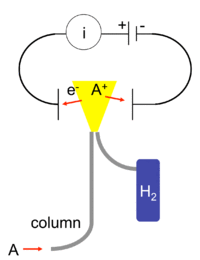

| FID를 이용한 HC 농도 측정 (1) 화염이온화 감지법(FID ;Flame Ionization Detection) 이란 탄화수소 농도는 일반적으로 불꽃 이온화 감지기(FID; Flame Ionization Detector)를 사용하여 측정한다. 미연탄화수소가 포함된 샘플가스는 수소 또는 수소-헬륨 불꽃에서 연소되고, 이온은 화학적 이온화 과정에서 소비되는 샘플가스 중 탄소에 의해서만 생성되므로 샘플가스가 유입되지 않은 상태에서는 생성되지 않는다. 이온전류의 크기는 미연탄화수소 농도 또는 미연탄화수소 중 탄소 원자의 개수를 통한 양적 측정을 제공한다. 빠른 응답의 FID 기구는 자동차 응용 여러 분야에서 탄화 수소 측정에 넓게 사용되고 있다. |

출처: <http://ws.ajou.ac.kr/~tperc/research_3.htm>

FID(Flame Lonization Detector) : 불꽃이온화 검출기

원리는 수소/Air에 의해 형성된 불꽃에서 시료가 연소되면 전하를 띤 이온이 형성되며, 이온의 농도에 비례하여 전류 흐름이 변화 된다. 구조는 jet(컬럼의 종류에 따라 사용되는 Jet의 크기가 구분), 수소 및 Air inlet, FID collector Assembly로 나뉜다. 주요 특징으로는 Sensitivity(대부분의 화합물에 대해 TCD의 약 103배 정도 감도가 높다.), Selectivity(수소/Air에 의한 불꽃에서 태워져 전하를 띤 이온을 생성하는 화합물만 검출할 수 있는 선택적인 검출기)이다.

FID에서 검출되지 않는 성분들 : Rare Gas (수소, 아르곤), 질소, 이산화질소, 일산화탄소, 이산화탄소, 사염화탄소, 이산화황, 산소, 물……등

주입구의 역할: 시료성분을 충분히 기화시키는데 최적인 온도 설정이 필요하므로 이를 맞춰 주어야 함.

(설정온도가 너무 높았을 경우 시료에 따라서는 분해를 일으키는 일도 있고 낮은 경우는 피크가 브로드하게 되는 일도 있기 때문에 주의가 필요)

1. 스프리트/스프리트레스 주입구

스프리트 주입구는 시료 부하용량이 작은 캐필러리 컬럼에 시료를 도입하기 위해서 고안, 시료주입구에서 도입되고 기화한 시료의 일부만을 분리컬럼에 이끌고 그 이외는 계외에 배출하는 장치로 피크를 샤프하게 하는 효과가 있다.

하지만 저농도의 시료분서에는 좋지 않다. 또 비점의 범위가 넓은 시료에서는 스프리트비가 일정하지 않는 경우도 있기 때문에 주의가 필요하다.

또 시료 도입시만 스프리트 가스를 멈추어 기화한 시료의 대부분을 캐필러리 컬럼에 도입하는 것이 스프리트레스 주입법이다. 용매의 큰 피크의 뒤에 테일링피크 부분을 없애는 것이나 컬럼항온조의 온도를 용매의 비점보다 낮게 억제하는 것으로 컬럼의 선단에 분석종을 농축하는 방법을 이용하는 것이 가능하여 저농도의 시료분석에도 대응 가능하다.

다만 스프리트 주입구와 스프리트레스 주입구의 어느 쪽이나 시료를 실린지로 도입해 기화시킬 단계에서 디스크리미네이션을 일으키는 일이 있어 성분의 비율이 바뀌어 버리는 일이 있기 때문에 주의가 필요하다.

스프리트 주입구는 스프리트레스 주입구를 겸하고 있는 경우도 많고 그 경우를 스프리트/스프리트레스 주입구라 부른다.

출처: <http://01041902024.tistory.com/149>

Flame ionization detector

From Wikipedia, the free encyclopedia

Jump to: navigation, search

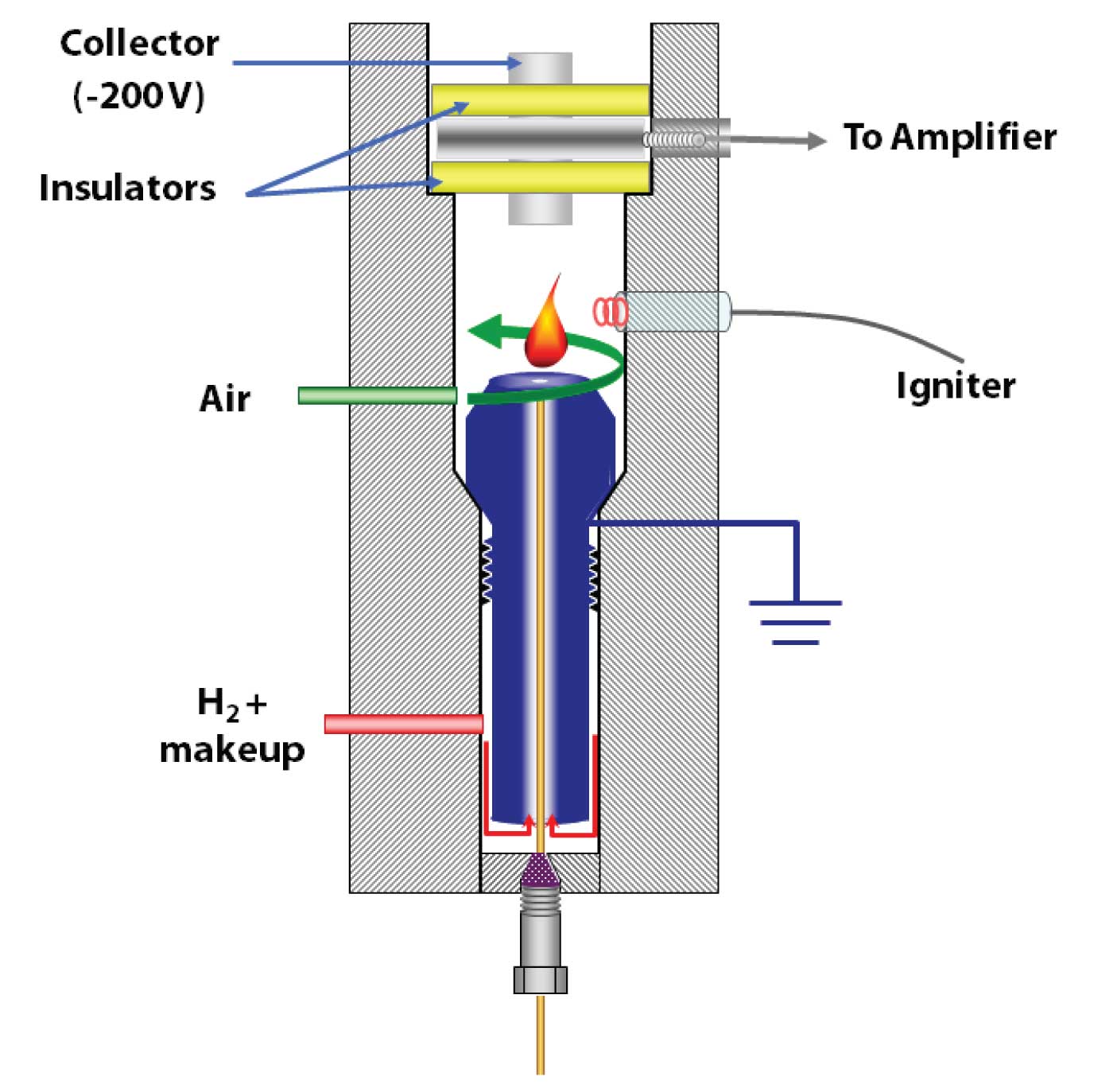

Schematic of a flame ionization detector for gas chromatography

A flame ionization detector (FID) is a scientific instrument that measures the concentration of organic species in a gas stream. It is frequently used as a detector in gas chromatography. Standalone FIDs can also be used in applications such as landfill gas monitoring, fugitive emissions monitoring and internal combustion engine emissions measurement[1] in stationary or portable instruments.

Contents

[hide]

- 1 History

- 2 Operating principle

- 3 Advantages and disadvantages

- 4 Operation

- 5 Description of a generic detector

- 6 See also

- 7 References

- 8 Sources

History[edit]

The first flame ionization detectors were developed simultaneously and independently in 1957 by scientists working for the Commonwealth Scientific and Industrial Research Organisation (CSIRO) in Melbourne, Australia.[2][3][4] and at the University of Pretoria in Pretoria, South Africa.[5]

In 1959, Perkin Elmer Corp. included a flame ionization detector in its Vapor Fractometer[6]

Operating principle[edit]

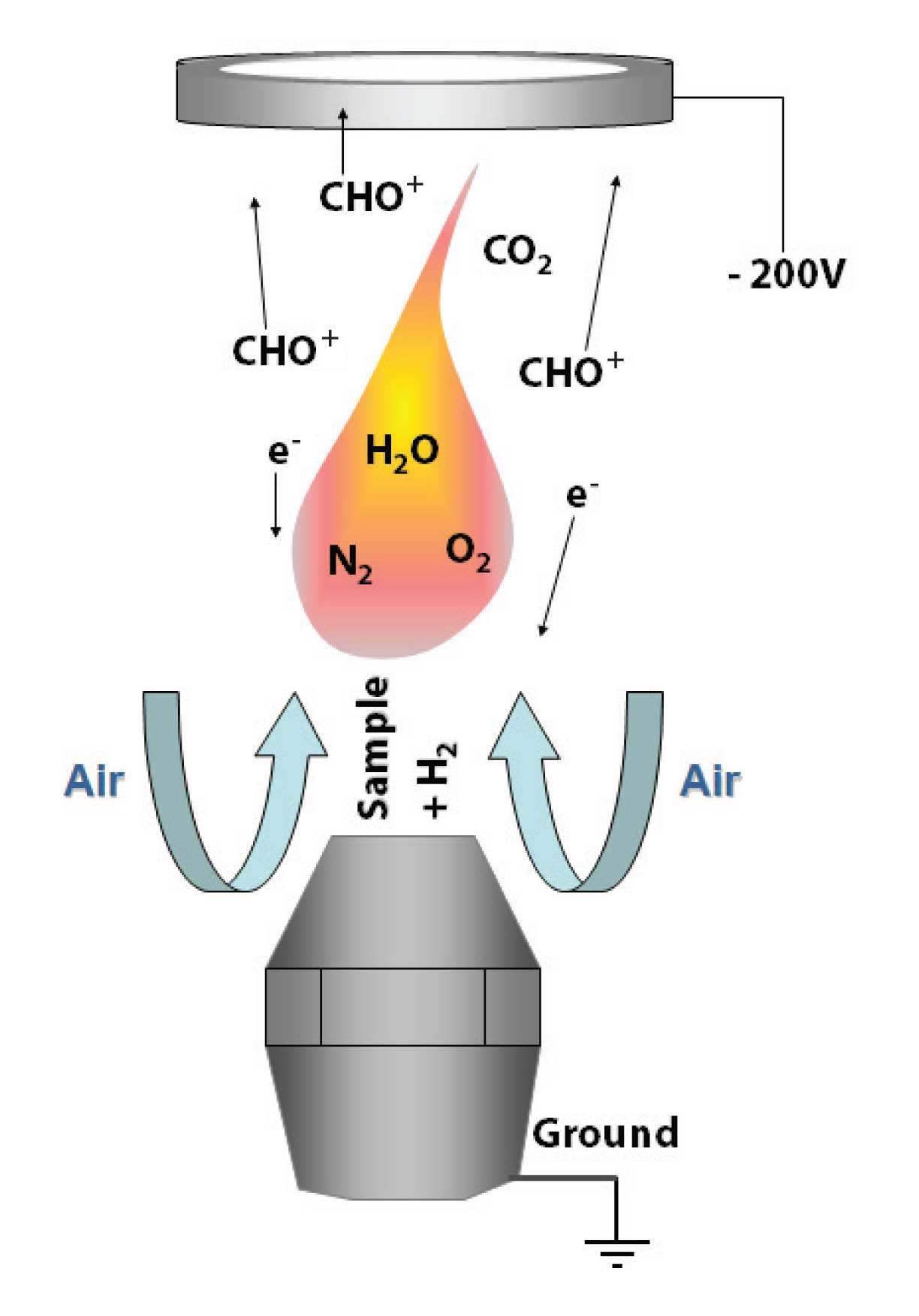

The operation of the FID is based on the detection of ions formed during combustion of organic compounds in a hydrogen flame. The generation of these ions is proportional to the concentration of organic species in the sample gas stream. Hydrocarbons generally have molar response factors that are equal to number of carbon atoms in their molecule, while oxygenates and other species that contain heteroatoms tend to have a lower response factor. Carbon monoxide and carbon dioxide are not detectable by FID.

Advantages and disadvantages[edit]

Advantages[edit]

Flame ionization detectors are used very widely in gas chromatography because of a number of advantages.

- Cost: Flame ionization detectors are relatively inexpensive to acquire and operate.

- Low maintenance requirements: Apart from cleaning or replacing the FID jet, these detectors require no maintenance.

- Rugged construction: FIDs are relatively resistant to misuse.

- Linearity and detection ranges: FIDs can measure organic substance concentration at very low and very high levels, having a linear response of 10^6.

Disadvantages[edit]

Flame ionization detectors cannot detect inorganic substances. In some systems, CO and CO2 can be detected in the FID using a methanizer, which is a bed of Ni catalyst that reduces CO and CO2 to methane, which can be in turn detected by the FID.

Another important disadvantage is that the FID flame oxidizes all compounds that pass through it; all hydrocarbons and oxygenates are oxidized to carbon dioxide and water and other heteroatoms are oxidized according to thermodynamics. For this reason, FIDs tend to be the last in a detector train and also cannot be used for preparatory work.

Operation[edit]

In order to detect these ions, two electrodes are used to provide a potential difference. The positive electrode doubles as the nozzle head where the flame is produced. The other, negative electrode is positioned above the flame. When first designed, the negative electrode was either tear-drop shaped or angular piece of platinum. Today, the design has been modified into a tubular electrode, commonly referred to as a collector plate. The ions thus are attracted to the collector plate and upon hitting the plate, induce a current. This current is measured with a high-impedance picoammeter and fed into an integrator. The manner in which the final data is displayed is based on the computer and software. In general, a graph is displayed that has time on the x-axis and total ion on the y-axis.

The current measured corresponds roughly to the proportion of reduced carbon atoms in the flame. Specifically how the ions are produced is not necessarily understood, but the response of the detector is determined by the number of carbon atoms (ions) hitting the detector per unit time. This makes the detector sensitive to the mass rather than the concentration, which is useful because the response of the detector is not greatly affected by changes in the carrier gas flow rate.

Description of a generic detector[edit]

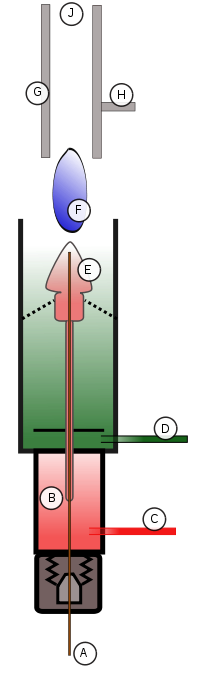

FID Schematic

The design of the flame ionization detector varies from manufacturer to manufacturer, but the principles are the same. Most commonly, the FID is attached to a gas chromatography system.

The eluent exits the GC column (A) and enters the FID detector’s oven (B). The oven is needed to make sure that as soon as the eluent exits the column, it does not come out of the gaseous phase and deposit on the interface between the column and FID. This deposition would result in loss of eluent and errors in detection. As the eluent travels up the FID, it is first mixed with the hydrogen fuel (C) and then with the oxidant (D). The eluent/fuel/oxidant mixture continues to travel up to the nozzle head where a positive bias voltage exists (E). This positive bias helps to repel the reduced carbon ions created by the flame (F) pyrolyzing the eluent. The ions are repelled up toward the collector plates (G) which are connected to a very sensitive ammeter, which detects the ions hitting the plates, then feeds that signal (H) to an amplifier, integrator, and display system. The products of the flame are finally vented out of the detector through the exhaust port (J).

See also[edit]

- Flame detector

- Thermal Conductivity Detector

- Gas Chromatography

- Active fire protection

- Photoionization detector

- Photoelectric flame photometer

References[edit]

- Jump up ^ "Flame Ionisation Detector Principles". www.cambustion.com. Retrieved 3 December 2014.

- Jump up ^ Scott, R. P. W., 1957, Vapour Phase Chromatography, Ed. D. H. Desty (London: Butterworths), p. 131.

- Jump up ^ McWilliam, I. G.; Dewar, R. A. "Flame Ionization Detector for Gas Chromatography". Nature 181 (4611): 760. Bibcode:1958Natur.181..760M. doi:10.1038/181760a0.

- Jump up ^ Morgan, D J (1961). "Construction and operation of a simple flame-ionization detector for gas chromatography". J. Sci. Instrum. 38 (12): 501. Bibcode:1961JScI...38..501M. doi:10.1088/0950-7671/38/12/321. Retrieved 2009-03-18.

- Jump up ^ Harley, J.; Nel, W.; Pretorius, V. (January 18, 1958). "Flame Ionization Detector for Gas Chromatography". Nature. doi:10.1038/1781244b0.

- Jump up ^ "Timeline". Perkinelmer.com. Retrieved 12 Dec 2014.

Sources[edit]

- Skoog, Douglas A., F. James Holler, & Stanley R. Crouch. Principles of Instrumental Analysis. 6th Edition. United States: Thomson Brooks/Cole, 2007.

- Halász, I. & W. Schneider. “Quantitative Gas Chromatographic Analysis of Hydrocarbons with Capillary Column and Flame Ionization Detector.” Analytical Chemistry. 33, 8 (July 1961): 978-982

- G.H. JEFFERY, J.BASSET, J.MENDHAM, R.C.DENNEY, "VOGEL'S TEXTBOOK OF QUANTITATIVE CHEMICAL ANALYSIS."

출처: <http://en.wikipedia.org/wiki/Flame_ionization_detector>

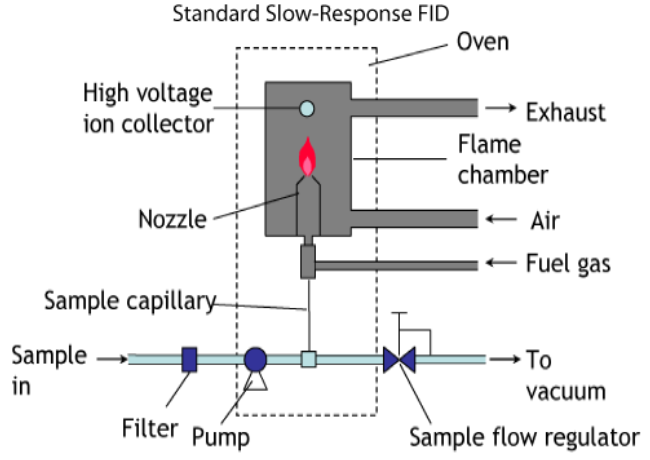

Fast FID Principles

The flame ionisation detector (FID) is the automotive emissions industry standard method of measuring hydrocarbon (HC) concentration.

The sample gas is introduced into a hydrogen flame inside the FID. Any hydrocarbons in the sample will produce ions when they are burnt. Ions are detected using a metal collector which is biased with a high DC voltage. The current across this collector is thus proportional to the rate of ionisation which in turn depends upon the concentration of HC in the sample gas.

The ionisation process is very rapid, so the slow time response of conventional FIDs is mainly due to sample handling. A typical slow analyser might have a response time of 1-2 seconds.

The Cambustion HFR fast response FID analyzers use conventional detection principles and a unique patented sampling system to give millisecond response times.

The Cambustion fast FID consists of a main control unit (MCU) and two remote sampling heads (which house the FIDs). The dual channel nature of the instrument enables simultaneous real-time measurement in two locations allowing, for example, evaluation of catalyst performance.

출처: <http://www.cambustion.com/products/hfr500/fast-fid-principles>

GC Solutions #11: The Flame Ionization Detector

by Matthew Klee

In this article we initiate a discussion on the workhorse detector of gas chromatography: the flame ionization detector.

The flame ionization detector (FID) is the premier detector in gas chromatography. It has unique properties and performance that puts it above and beyond all other general-use detectors in gas chromatography (or any other form of chromatography, for that matter).

Topping the list of unique attributes are (1) unit carbon response and (2) wide linear operating range (up to 7 orders of magnitude). When combined with its other attributes of low cost, ease of use, speed of response, and ruggedness, it is no wonder why the FID is the premier detector of choice for GC.

The FID is a mass sensitive detector. That means that its response is proportional to the mass of carbon that passes through it. In that regard, FID response is stated in terms of picograms carbon per sec. Detection limits for FIDs are in the low pg C /sec.

Unit carbon response means that the FID responds linearly to the mass of carbon flowing through it, independent of compound structure. The FID gives unit response for most hydrocarbons within a couple per cent error. Exceptions to this will be discussed next month. This attribute of unit carbon response allows one to quantify mixtures without having calibration standards for every component. Amounts of components in a sample relate to their relative peak areas. So, a simple area per cent report will fairly closely reflect the mass per cent of each component in a mixture. This is extremely useful when analysing complex samples such as those in the petroleum industry wherein samples can contain well over 1000 components. In the same vein, the relative ratio of the area of one peak to another (e.g., the peak of an unknown component relative to a calibrated reference peak) closely reflects its relative amount in the sample. This is useful when estimating concentration levels of components in a sample when identities are unknown or when standards are not available for calibration.

The FID was first described by two independent groups at approximately the same time [1,2]. FIDs were commercially available soon thereafter (the early 1960s.) Most of the developments since the original functional designs have been primarily in areas of usability, adaptation for capillary instead of packed columns, and in improvements of associated electronics, and signal processing.

The Flame

In a hydrogen flame, hydrogen gas (H2) reacts exothermically with the oxygen (O2) to form water. A hydrogen/air flame temperature burns at 2210 °C.*

2H2 + O2 4H• + 2O• 2H2O + heat

In the above reaction, one part oxygen reacts with two parts hydrogen. This ratio (1:2) is called the stoichiometric ratio. Because air is approximately 20% oxygen (O2), a stoichiometric mixture would require an air/hydrogen gas flow ratio of 2:5; 2.5 times more air than hydrogen. Although stoichiometric ratios of oxygen to hydrogen can provide a reasonable dynamic range for the FID, experience has shown (in part because of the complex combustion processes described below) that an excess flow of air is required to ensure complete combustion, unit carbon response and the widest linear dynamic range. In addition, higher than stoichiometric air flow helps to avoid carbon deposits from forming in the jet when high concentrations of analyte or solvent pass through.

A ratio of at least 6:1 of air to hydrogen has empirically been found necessary to achieve the widest dynamic range possible with FID. Many manufacturers recommend ratios of 10:1 or more air/hydrogen flows. The higher the sample load to the FID, the more flame gases are required to prevent blowout and carbon formation. That is why gas flows used with packed columns (higher sample loads) generally need to be higher than when capillary columns are used. Exact flow rates are somewhat instrument specific and also relate a bit to carrier gas flow rates, so following manufacturer recommendations is wise.

Sample Combustion and Signal Generation

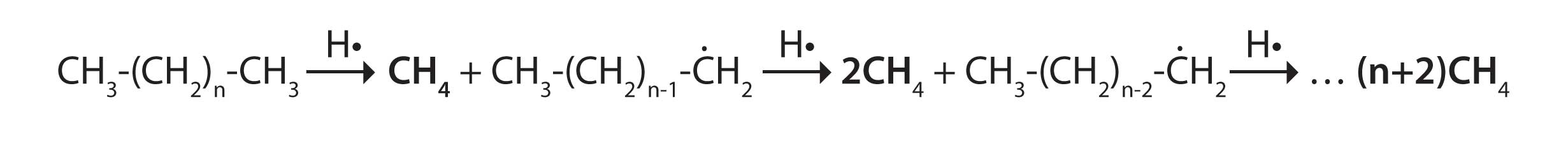

A very nice explanation of FID flame chemistry has been provided by Holm [3]. Therein he supports a mechanism whereby most organic compounds are reduced to saturated counterparts in the initial portion of the flame, where temperatures are lower. As they continue up the flame, these saturated counterparts then continue to react with hydrogen atoms to form methane, as illustrated in Equation 1.

Still further in the flame, methane is combusted to form formylium ion CHO+, the primary FID signal-producing ion.

CH4 → H2 + :CH O•→ CHO* CHO+ + e-

Other reactions can of course occur, including ones that form other positive ions such as hydronium ion.

CHO+ + H2O H3O+ + CO

All positive ions are collected by a negatively biased collector causing a current to flow, which is then electronically amplified and digitized (Figure 1). The current is proportional to the number of ions collected. The yield of ions from carbon passing through the detector is on the order of one ion per 106 carbon atoms [4], yet this is still enough for the FID to give picogram-level detection. Electrons in the flame flow in the opposite direction and are grounded out on the FID jet (Figure 2). By biasing the collector high enough relative to the jet (e.g., -200 V), recombination of positively charged ions and electrons is minimized, and signal maximized.

References

1. J. Harley, W. Nel and V. Pretorious, Nature , London, 181(1958)177.

2. I. G. McWilliams and R. A. Dewer, “Gas Chromatography 1958”, (Ed. D. H.Desty), Butterworths Scientific Publications (1957) 142

3. T. Holm, J. Chrom. A , 842 (1999) 221–227

4. D.K. Bohme, in: P.J. Ausloss (Ed.), Kinetics of Ion–Molecule Reactions, Plenum Press, New York, 1979

Dr Matthew S. Klee is internationally recognized for contributions to the theory and practice of gas chromatography. His experience in chemical, pharmaceutical and instrument companies spans over 30 years. During this time, Dr Klee’s work has focused on elucidation and practical demonstration of the many processes involved with GC analysis, with the ultimate goal of improving the ease of use of GC systems, ruggedness of methods and overall quality of results.

출처: <http://www.sepscience.com/Techniques/GC/Articles/208-/GC-Solutions-11-The-Flame-Ionization-Detector>

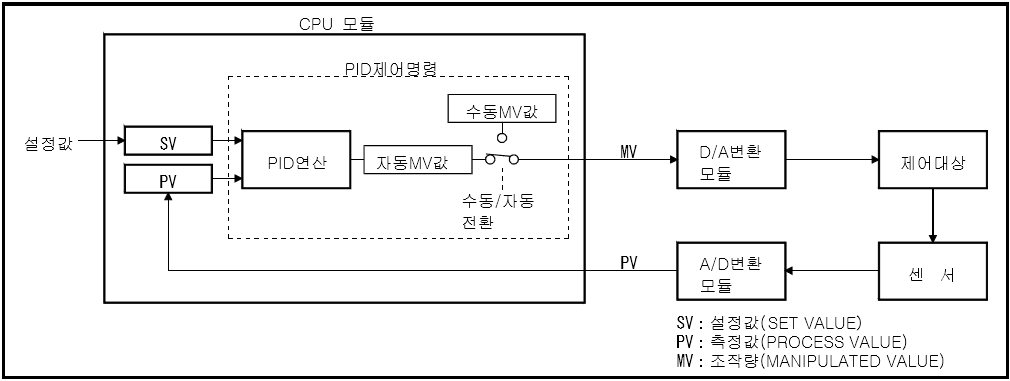

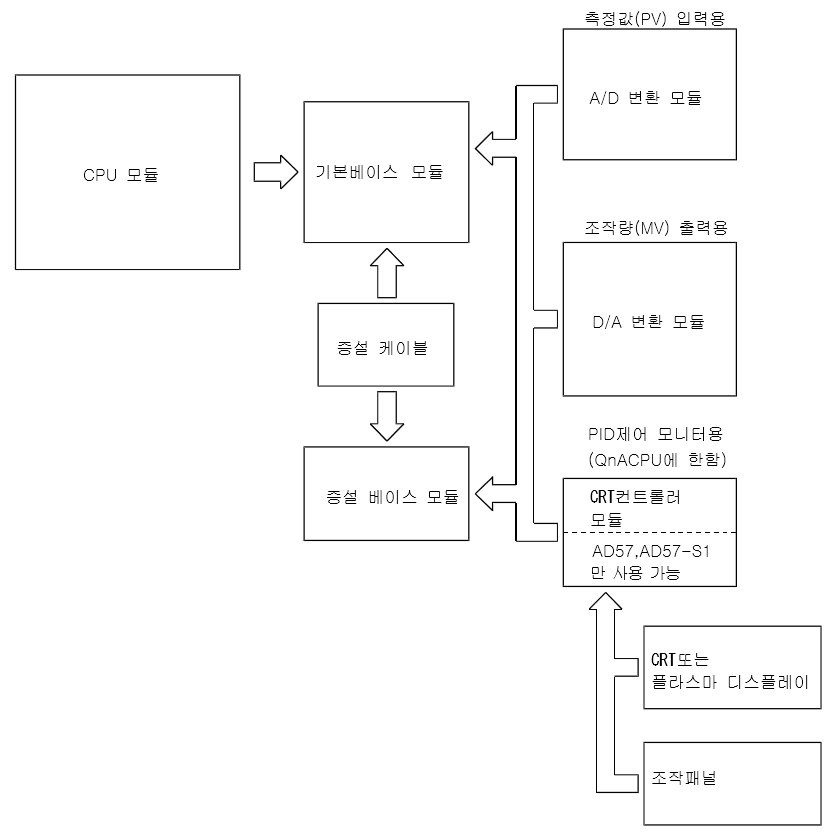

PID Control in Melsec

화면 캡처: 2018-11-02 오전 09:54

SV Set Value

PV Process Value

MV Manipulted Value

화면 캡처: 2018-11-02 오전 09:55

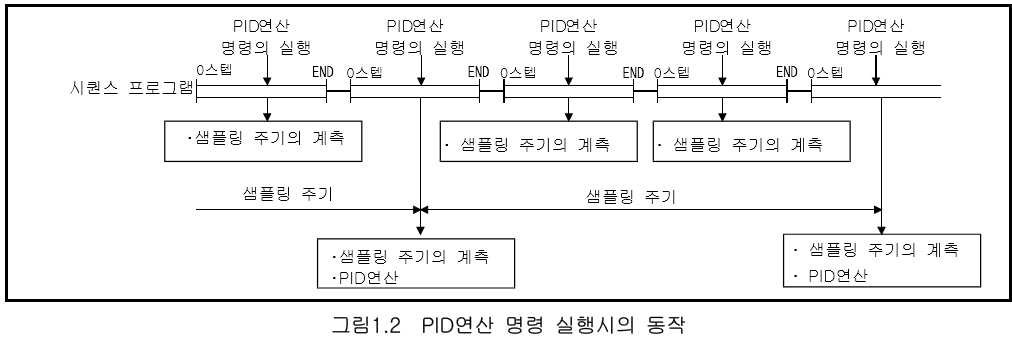

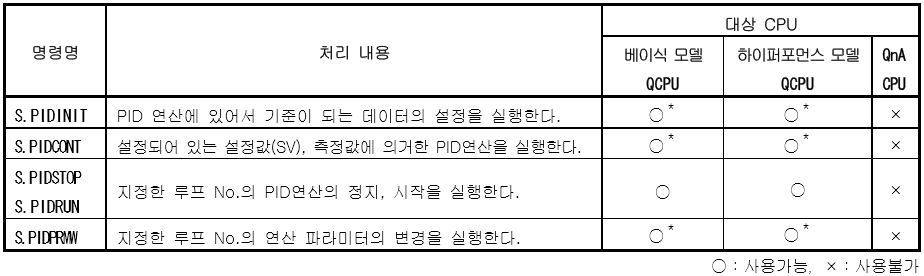

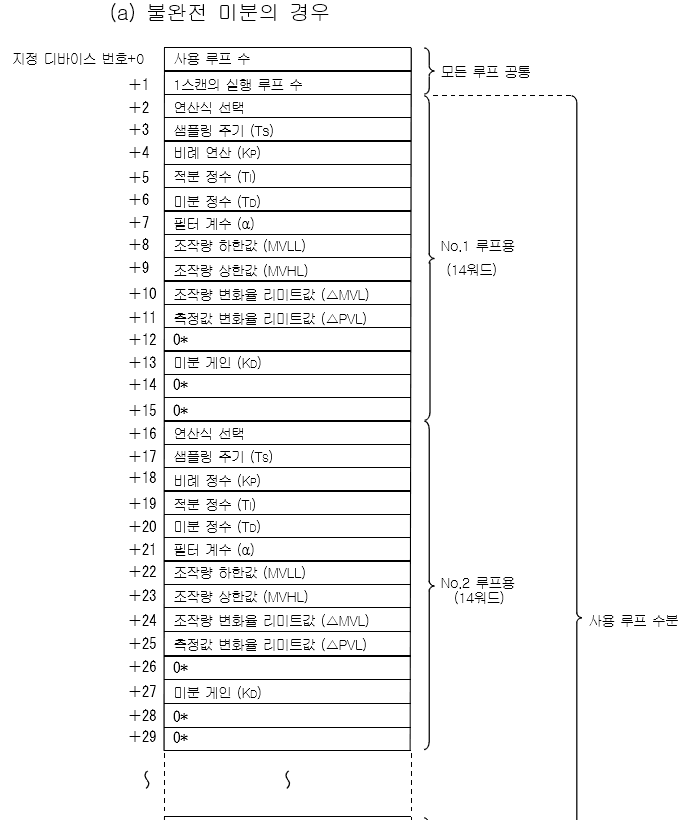

PID 연산 명령에는

S.PIDCONT 불완전 미분

PIDCONT 완전미분

화면 캡처: 2018-11-02 오전 09:57

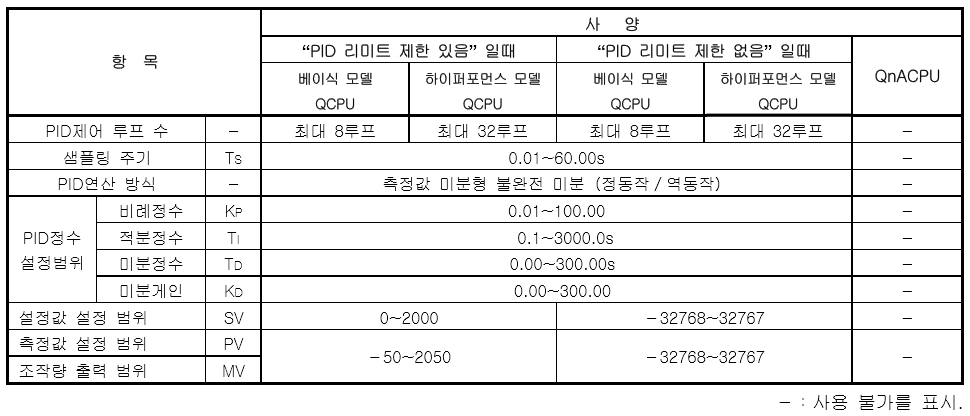

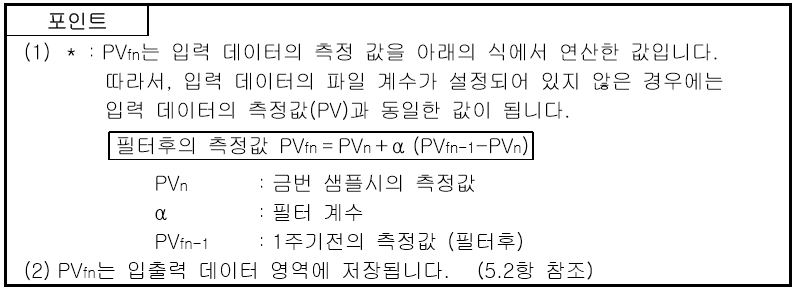

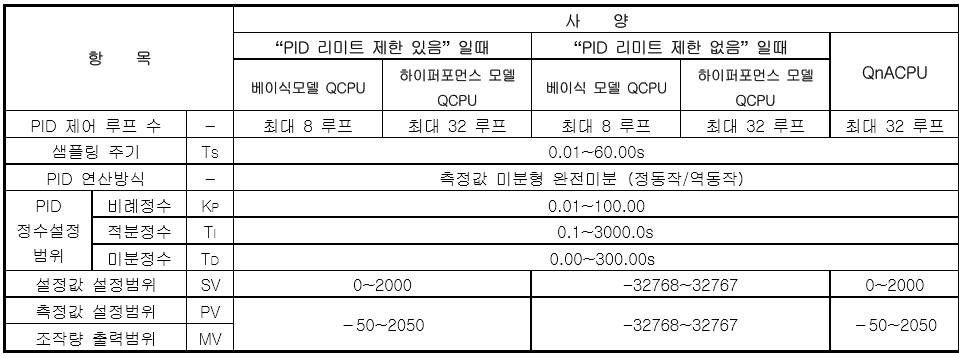

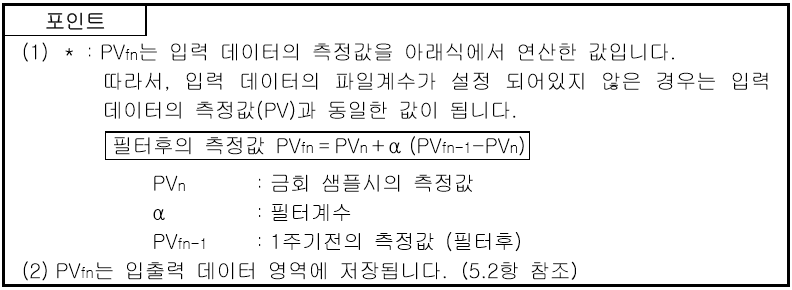

불완전미분에 대한 성능, 사양

화면 캡처: 2018-11-02 오전 09:58

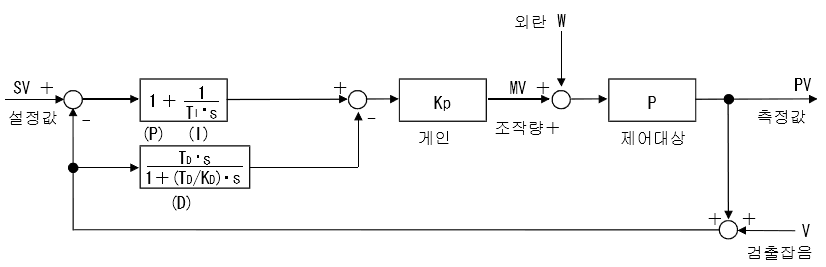

불완전 미분에 대한 블록도

화면 캡처: 2018-11-02 오전 09:59

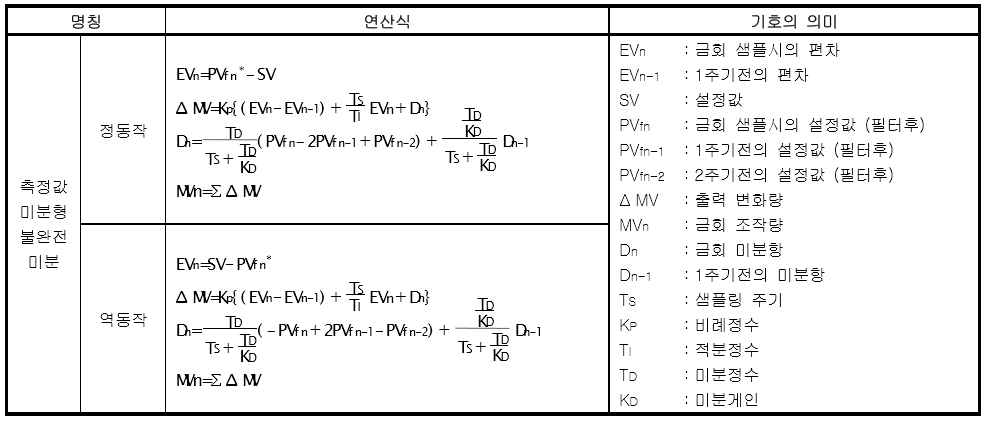

불완전 미분에 대한 연산식

화면 캡처: 2018-11-02 오전 10:00

화면 캡처: 2018-11-02 오전 10:01

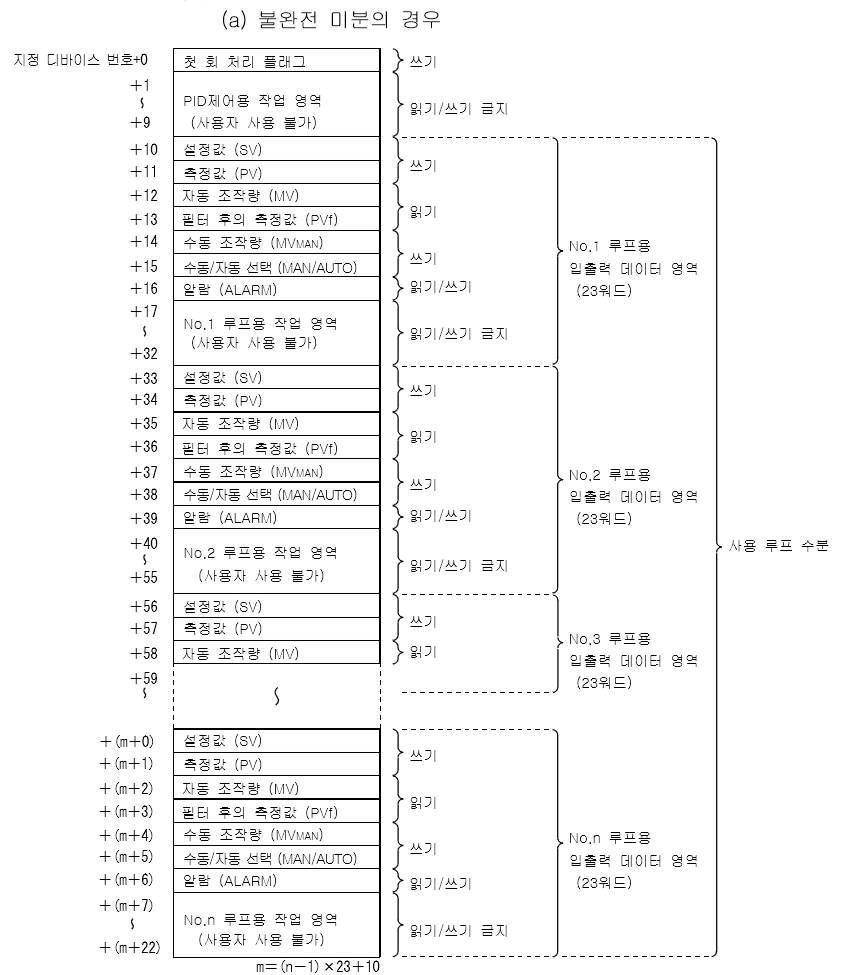

불완전미분에 대한 제어 명령

화면 캡처: 2018-11-02 오전 10:02

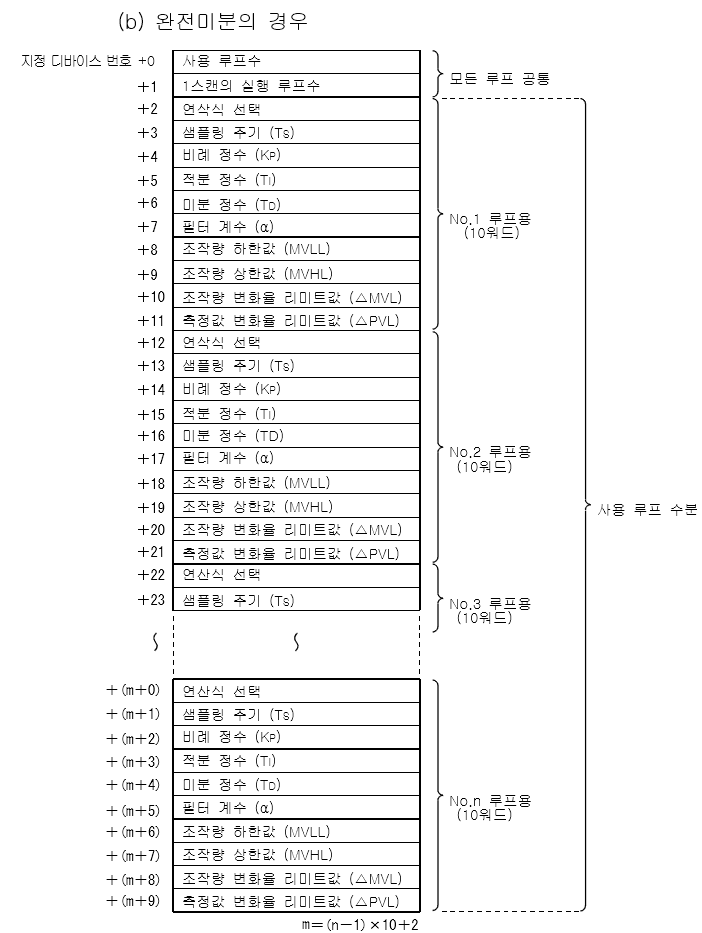

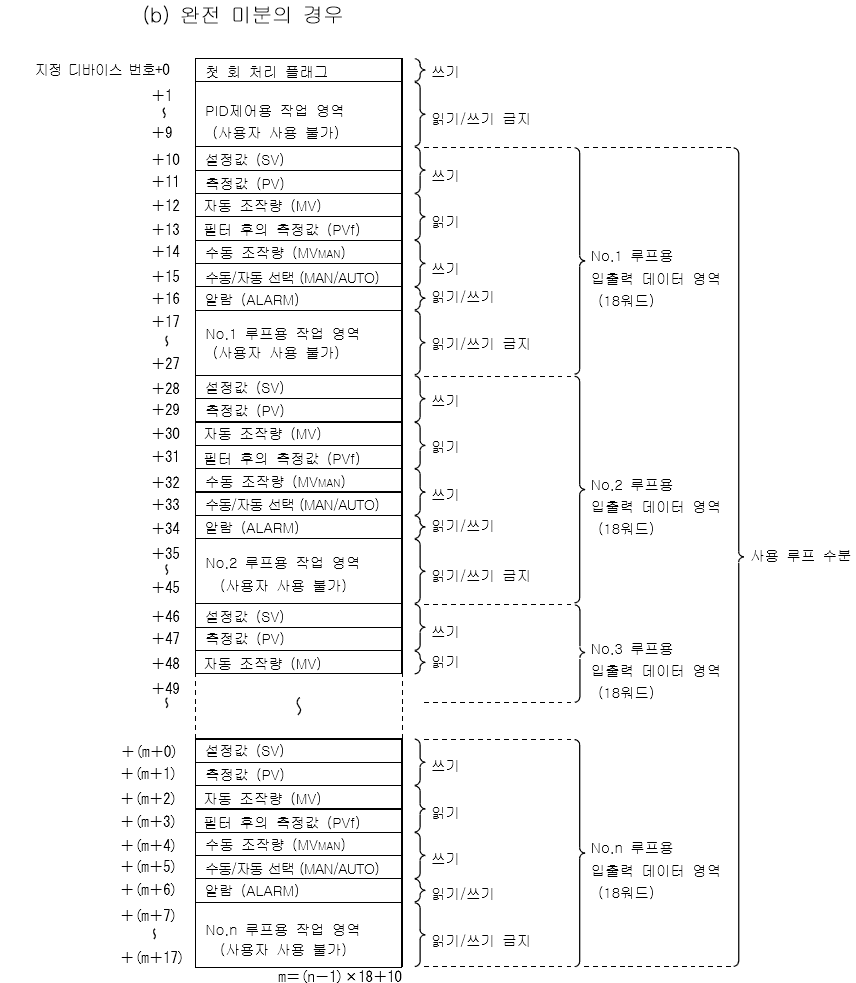

완전미분에 의한 PID 제어

화면 캡처: 2018-11-02 오전 10:06

PID 연산 블록도

화면 캡처: 2018-11-02 오전 10:07

화면 캡처: 2018-11-02 오전 10:07

화면 캡처: 2018-11-02 오전 10:07

PID 제어 명령

화면 캡처: 2018-11-02 오전 10:08

PID 제어의 기능

2018-11-02 오전 10:10

화면 캡처: 2018-11-02 오전 10:11

화면 캡처: 2018-11-02 오전 10:11

화면 캡처: 2018-11-02 오전 10:11

화면 캡처: 2018-11-02 오전 10:12

화면 캡처: 2018-11-02 오전 10:15

화면 캡처: 2018-11-02 오전 10:14

화면 캡처: 2018-11-02 오전 10:15

화면 캡처: 2018-11-02 오전 10:16

화면 캡처: 2018-11-02 오전 10:35

화면 캡처: 2018-11-02 오전 10:17

화면 캡처: 2018-11-02 오전 10:42

화면 캡처: 2018-11-02 오전 10:36

화면 캡처: 2018-11-02 오전 10:42